The Vacuum Pump – A Winemaker’s Best Friend!

When I first started making wine, I never would have imagined that a Vacuum Pump would end up being one of my most treasured pieces of wine making equipment. After using it I have to wonder what I ever did without it. Don’t get me wrong, I am not saying that a vacuum pump is required for wine making. I just makes the process a lot more pleasurable. Allow me to explain.

Some of the areas of difficulty in wine making are lifting heavy containers of wine and degassing. A vacuum pump setup, like the one I will show you how to build, can make these tasks much easier. In fact, you may never have to lift up a heavy carboy of wine again.

IMPORTANT NOTE: Only use the with GLASS Carboys. Plastic Carboys WILL CRUSH UNDER THE PRESSURE!

Vacuum pumps are used by people in the medical respiratory industry and by folks who work on air conditioners. They plug into your standard electrical outlet using household current. A standard basic vacuum pump will work just fine for this application.

You can find vacuum pumps HERE.

Do make sure you fill it with the appropriate oil specifically designed for Vacuum Pumps.

Wait, Did You Say A Vacuum Pump Can Save My Back In Wine Making?

Yes I did! As you probably already know, a six gallon carboy of wine can be quite heavy. In order to rack or transfer the wine using a siphon, you need to have one carboy physically at a higher elevation than the other. This usually involves lifting a heavy jug of wine that you want to transfer to a counter top. Doing so can agitate sediment while you are lifting and moving the wine. It also can be hard on the back! When racking with a Vacuum Pump however, you don’t need to rely on gravity to transfer the wine with a siphon. In fact, you can easily transfer the wine in the opposite direction or simply have both carboys on the same level.

Another benefit of using a vacuum pump setup when making wine is that it really does an excellent job degassing the wine. In fact, when I transfer the wine, it does most of the degassing at the same time! How cool is that! Check out my latest wine making videos to see it in action! I believe you can get more CO2 out of the wine using vacuum degassing than using any other method.

As a side note, degassing wine is very important. Most wines are supposed to be completely flat, meaning no bubbles. In order for many wines to clear properly the wines need to be completely degassed. You can degas your wine by:

- Stirring with a long handled spoon – Very labor intensive and about as much fun as walking uphill to school in the snow. This is a great way to build up your arm muscles if you want to forgo that gym membership.

- Using a drill mounted whip or mix-stir – Works well, but still requires a lot of stirring.

- Using a Vacuum Pump setup like this one – Works very well with next to no effort.

The Sicilian Prince Vacuum Pump Setup For Wine Making

This is my setup. It was inspired by a similar design I read about in a book by Stephen Hughes. I highly recommend that book for wine making do it yourself projects. My vacuum pump setup is a little different then Steve’s. I believe that while his is probably better, mine is a bit easier to build.

Parts for the Vacuum Pump Setup

- A Vacuum Pump

- Two Racking Canes

- Carboy Cap

- Hose

- 3 Valves

- Barb connectors the fit you hose and valves ( I used 1/4″ Barbs)

- A 1/4″ barb – 1/4″ Barb straight fitting

- A 1/4″ barb T Fitting

- Two 1/4″ barb Elbow Fittings

- A 1/4″ barb fitting that will allow you to connect hose to your Vacuum Pump

- A Jar with a Lid

- Silicone

- Some Creativity

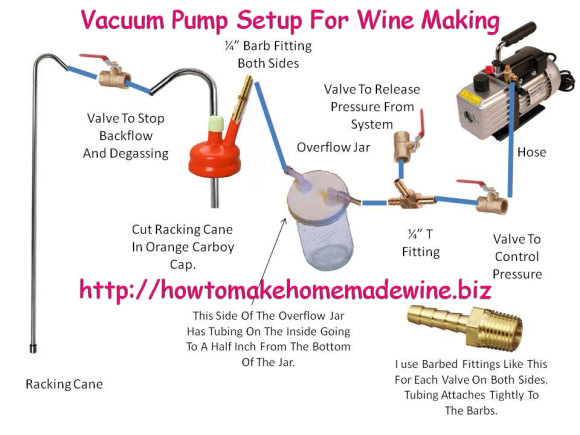

Assemble the Vacuum Pump system as you see in the picture. The blue lines are where the hoses connect. Be sure to pick one racking cane that is skinny enough to fit in your carboy cap. Cut the bottom off so that only 8 or so inches goes down into the carboy that will be receiving the wine.

Take care to use the Overflow Jar. If wine backs up into the vacuum pump, it will break.

Please look at this video that I made to see how I built that Overflow Jar.

A piece of hose need to be inserted in the jar on the side that connects closest to the carboy. Make sure that hose goes to about a 1/2 inch from the bottom of the jar. This will direct overflow wine to the bottom of the jar.

When using the vacuum pump system, be sure to have all of the valves open except the one marked “Valve to release pressure from the system”. That valve needs to be closed while the vacuum pump is turned on. After shutting off the pump, there will still be vacuum pressure in the system. If you need to relieve that pressure, simply open the valve.

If you need to control the overall pressure in the system, use the valve marked “Valve to control pressure”. Most of the time, I use this completely open. But if the bubbles are getting too close to the top of the carboy while it degasses, you may want to adjust this to reduce the pressure.

Finally, there is the other valve that is between the carboys. While it is open, you will transfer wine from one carboy to the other. If you close it, you will be in degassing mode. You may also want to close it after transferring wine if the receiving carboy is physically higher than the sending carboy. This will prevent a reverse siphon from starting.

Before using the vacuum pump setup, I run a gallon of B-Brite solution thru it to clean the complete system. After scrubbing and cleaning the carboy and cap, I pour out the cleanser and pump about two gallons of clean water thru the system to rinse it out. After doing so, I am ready for my wine making adventure. When complete, I clean the system by doing the same procedure again.

It is important to understand that I have next to no plumbing experience. There may be other ways to make this vacuum pump setup that use cheaper parts. I bought most of the parts in the hardware section of Lowes, but I am sure that any hardware store probably stocks these parts as they are commonly used in plumbing.

Well, that is my complete Vacuum Pump Wine Making System! I hope you enjoy it and perhaps decide to make one. If I can make one, just about anyone can. If you make a lot of wine, you will want one.

Cheers!

One plastic “carboy” won’t crumple up. My new Intellitakns are designed to handle as much as you can throw at them.

Hello Steve!

Thanks for stopping by my site.

First off, I would like to say that I love your book! It is a treasure in my library!

About the plastic carboy, You may have the only plastic carboy on the market that will not be destroyed by the vacuum degassing. Your carboy is very unique, and if it is like anything else you do, most probably outstanding.

Here is the thing… I try to minimize the exposure to plastics in most things, especially for things that sit over time. That is why I don’t buy bottled water. I have a house filter…. I use plastic primary fermenters and all glass secondary carboys, as my wine tends to sit is the secondary for a much longer period of time.

There are definite advantages to plastics, I admit. But I tend to prefer glass. All that being said, allow me to discuss your product.

Steve, everything I have seen from you has excellence and quality all over it. I have no doubt that your Intellitanks are quality. However, quality comes at a price. Your six gallon carboy costs about $100. I can get almost 3 six gallon glass carboys for the same cost. Does the cost difference justify getting it? I don’t know, I will have to find out.

Steve, I am willing to give one of your carboys a try if you can honestly tell me that after knowing my preferences that you think it would be worth doing for me. I would probably buy one and do a review in the new year. Cash is a little tight right now with the holidays coming, unless I can convince Mrs. Santa to get one for me.

I only recommend things that I honestly believe in. If it is something that I love, I will let it be known. If I love it AND you sell it thru amazon, which I have an affiliate agreement with, I will even promote and sell it from my website. The small amount of money that I earn on this site helps defray the costs of my wine making hobby and get me to try new things that I normally wouldn’t try.

Please let me know how you feel about it, and if you think it is worth my while. All I can promise is a truthful, honest and unbiased review.

Hello,

I’m thinking about either sweet talking my husband into building a vacuum pump for me or buying one that is highly rated on a forum that sells for about $200. If you don’t mind, how much did you invest on the one you made? Also, I learned to how to make wine from kits on your youtube videos, do you happen to have a video posted that uses the vacuum pump to rack and then also demonstrates how to use it for degas? Thanks!!! and thanks again for your educational videos, very helpful!! Love this hobby!

Hello Wendy,

Thanks for your kind words… I would say that my vacuum pump cost under $70 dollars, and the rest is tubing and valves. You don’t need the expensive ball valves I used. You could use the plastic ones for home irrigations systems… All in all, I think you would be able to make a system for about $125 or less…

I think my Blackberry wine from last year I used it for Racking and Degas. I just put a Blueberry wine video up today with it for DeGasing.

Thanks for your kind words and for visiting my channel and website. It is a cool hobby.

Hello everyone,

This has been a fascinating topic to me. I have learned about it recently, and especially interested in it since all of my wine is stored in the large 14.5 gallon demijohn bottles…. and I have recently learned that I have a bulging disc in my lower back.

In the short time that I have been reading and searching on this topic, it seems that everyone talks of vacuum racking from 5 or 6 gallon carboys or barrels. I have a few 5 gal carboys, but it is not enough for my winemaking needs, so I had upgraded to four of the large demijohns. As I’m sure you know, these have a much thinner glass wall thickness than the usual 5 gal carboys.

So naturally, my question turns to vacuum racking from these delicate giants. Is it possible? How? What are the limitations?

Thank you so much for any assistance you can offer with vac racking between these large bottles.

Sincerely,

Dan

I would imagine it is possible. As long as it is not plastic.

Hey sicilian prince hope all is well I made the vacuum pump today under 100 bucks thanks for sharing that with us. It works great I tried it on a small jug got it to a 30 inch vacuum. My question to you is how long do you run it for or just until the bubbles get large and few of them? I made fittings to fit my larger tanks and 2 I’ll try it out in time. On the variable tanks do you think it would work fine if I raised the pressure in the gasket? Have you experiment with a variable tank? Thank you once again

I run it until the bubbles get bigger. I have not experimented with a variable tank.

Thank you i will let you know how it works out with variable tank I will do it when I am off in two weeks just to see how well it works out I used it on a chilian carmenère wine I had made in a solid tank and it worked well the only down fault to it is I can not see inside the tank to know how it was doing but I was able to check it with the gauge and once I was down to a 30 inch vacuum I let it sit there for 30 minutes then did a test with the hydrometer tube and it worked out fine.hey everyday is a learning experience. Thank you once again for the show of the vacuum pump

Vito – how did it turn out with your variable tank, and what tank do you have (manufacturer, model, size)? Thank you in advance!

Hello Sicilian Prince – I built a system for myself exactly as you described. I have a number of questions I hope you can help with. When strictly using the system for degassing, when do you know it’s finished? Also I noticed what was clean oil yesterday in the vacuum pump now is cloudy after less than 20 minutes of run time. Any idea on why?

When the bubbles start to get larger, then it is finished… All depends on how warm the wine is and how much co2 is in it…

Taste it.. Does it seem fizzy?

I would change your oil.